Authors: Aziliz Guezou-Philippe, Arnaud Clavé, Ehouarn Maguet, Ludivine Maintier, Charles Garraud, Jean-Rassaire Fouefack, Valérie Burdin, Eric Stindel, Guillaume Dardenne

Published on: March 22, 2024

Impact Score: 7.8

Arxiv code: Arxiv:2403.15353

Summary

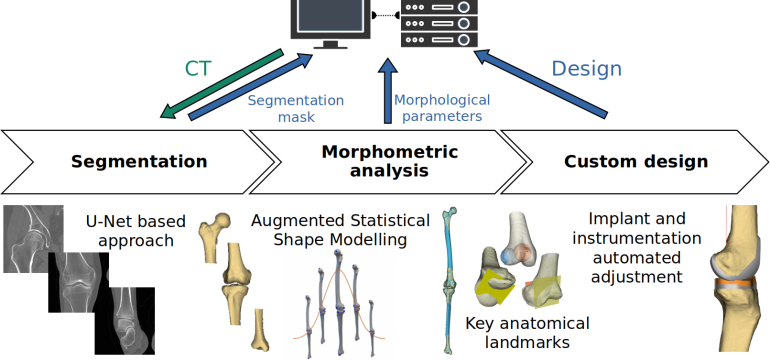

- What is new: A fully automated workflow for designing patient-specific knee implants using artificial neural networks and augmented statistical shape models, significantly reducing the time and manual effort required.

- Why this is important: Current solutions for personalized arthroplasty, specifically knee implants, are too slow and require manual intervention, making it challenging to integrate them into clinical routines.

- What the research proposes: The study introduces an automated pipeline that uses machine learning and shape modeling to create custom knee implants directly from patient CT scans, significantly reducing design time.

- Results: The workflow showed high accuracy in all steps: $0.4\\pm0.2mm$ for segmentation, $1.2\\pm0.4mm$ for bone reconstruction, and $0.6\\pm0.2mm$ for the final implant fitting, with the entire process taking about 5 minutes.

Technical Details

Technological frameworks used: Machine learning, Computer Vision

Models used: Artificial Neural Networks, Augmented Statistical Shape Models

Data used: 91 CT scans for training, 41 CT scans for evaluation

Potential Impact

Orthopedic implant manufacturers, Hospitals and clinics performing knee arthroplasty, Medical imaging software companies

Want to implement this idea in a business?

We have generated a startup concept here: CustomFit Ortho.

Leave a Reply