SmartCompress

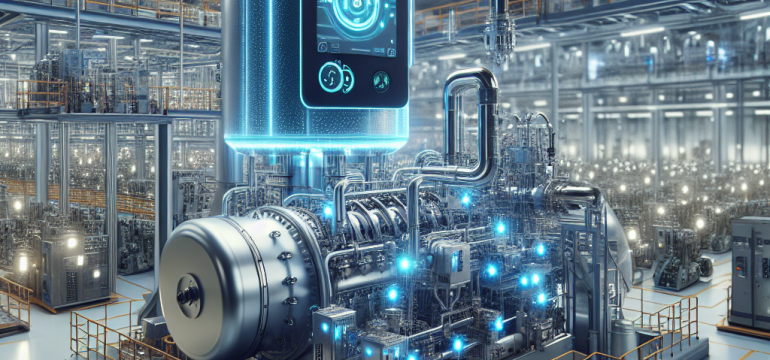

Elevator Pitch: Imagine never having to worry about your HVAC or refrigeration systems breaking down unexpectedly. SmartCompress leverages cutting-edge IoT and AI to predict and prevent faults in compressor-based machines, ensuring they operate efficiently and saving you time and money on emergency repairs and energy bills. Join us in revolutionizing how we maintain the machines crucial to our daily lives and industries.

Concept

An IoT-based predictive maintenance platform for compressor-based machines

Objective

To enhance the operational efficiency and extend the lifespan of compressor-based machinery in industrial and residential settings through advanced monitoring and predictive analytics.

Solution

Utilizing IoT sensors and advanced machine learning algorithms, SmartCompress will offer real-time monitoring, fault detection, fault prediction, and operational forecasts for compressor-based machines.

Revenue Model

Subscription-based for continuous monitoring and predictive maintenance services, with tiered pricing based on the number of devices monitored.

Target Market

Manufacturing industries, commercial buildings, and residential complexes with significant reliance on HVAC systems, refrigerators, heat pumps, and chillers.

Expansion Plan

Start with local industries and residential complexes, gradually expanding to national and then international markets. Partnering with HVAC and refrigeration service companies for broader outreach.

Potential Challenges

Technical integration with a diverse range of machines, data privacy concerns, and convincing stakeholders of the ROI for investing in predictive maintenance.

Customer Problem

Unexpected breakdowns of compressor-based machines, resulting in costly repairs and downtime.

Regulatory and Ethical Issues

Compliance with data protection laws (e.g., GDPR) and ensuring customer data confidentiality and integrity. Ethical use of predictive data without exploiting customer vulnerabilities.

Disruptiveness

Transforms traditional reactive maintenance models into proactive, predictive maintenance frameworks, significantly reducing operational costs and extending equipment lifespan.

Check out our related research summary: here.

Leave a Reply